User-check prerequisites for LED UV-A lamps, and how to plot the light emission of an LED UV-A lamp for Airbus AITM6-1001 Issue 11

The client check necessities for LED UV-A Lamps keep on developing as Aerospace Primes have more insight and criticism from their provider organization. Beforehand, we portrayed How to Check LED UV Stability to consent to Airbus AITM 6-1001 Issue 11. From that point forward, Airbus has changed the observing prerequisites for clients. LED UV Stability is not, at this point a month to month client check, anyway new and diverse client checks are required. This is what you need to know.

Monthly Checks

Per Airbus Memorandum ME1720084, four monthly checks are needed for all LED lights utilized for assessment: Beam Variability, Minimum Working Distance, Beam Irradiance Profile, and Maximum Irradiance. The aftereffects of these four checks must be recorded in a composed report. A portion of these will be recognizable, however, as of recently, the others have simply applied to light producers.

Maximum Irradiance Check

Checking the Maximum Irradiance is equivalent to a typical UV-A lamp intensity check. The lamp is held at a fixed good ways from the UV-A meter and the irradiance is confirmed in µW/cm2. For Airbus, this check is performed at the individual lamp working distance. As a feature of Airbus and Rolls-Royce accreditation, lamp producers will confirm the working distance of every individual lamp for the maximum irradiance of 5,000 µW/cm2, and the outcome is recorded on the light affirmation. That working distance should be utilized instead of the standard 15 in/38 cm distance to agree to the most recent Airbus necessities.

Most UV-A lamps available are set to give 5,000 µW/cm2 good ways off of 15 in/38 cm. Realize what’s so uncommon about those numbers here.

Beam Variability Check

The Beam Variability can be confirmed during a customary “White Paper” check. The light has held a ways off from a huge sheet of white paper, and the bar is noticed. There should be no conspicuous intensity fluctuations, flash or strobing, similarly as there shall not be any evident bright or faint spots inside the pillar. Note that this is an abstract check and is recorded as either satisfactory or unsuitable. Photograph documentation isn’t needed.

Minimum Working Distance Check

The other two month to month checks are new for clients. The strategies are given in ASTM E3022, which is a detail expected for lamp producers. Per E3022, the Minimum Working Distance is the most limited distance the lamp can be utilized before the pillar isn’t uniform. Fortunately, it tends to be effortlessly confirmed during a customary “White Paper” check. After checking the Beam Variability above, gradually draw the light nearer to the white paper until the shaft design shows an obvious non-consistency or individual LEDs become particular. The distance where the bar is non-uniform is recorded as the Minimum Working Distance. To completely follow Airbus prerequisites, the most extreme force of 5,000 µW/cm2 will probably be reached before the Minimum Working Distance per E3022.

Realize what to consider when searching for another UV-A light for fluorescent penetrant testing or magnetic particle inspection here.

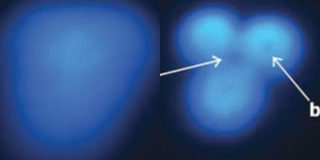

ASTM E3022, FIG. 2

Example of Uniform and Non-Uniform Projected Beams

for Determining Minimum Working Distance

Beam Irradiance Profile Check

The last month to month check is the Beam Irradiance Profile. The previous user-checks can be done simply with little changes done in the method that already there, validating the beam profile of an LED lamp. Thorough techniques that are observed in E3022 Section 7.4, and Airbus also has identified minor changes as well.

- Mount the light over a level workbench at the individual lamp working distance (with 5000 µW/cm2 maximum intensity from the individual lamp certification).

- Turn on the lamp and permit it to balance out. E3022 determines in any event 30 minutes before taking any estimations.

- Utilize an aligned UV-A radiometer to locate the most extreme irradiance at the focal point of the beam and record the intensity.

- Beginning from the middle as a zero-point, move the UV-A sensor along the side and record the intensity utilizing a 0.5 in/13 mm lattice, planning the full-beam profile until the power dips under 200 µW/cm2.

- Utilizing this information, make a 2-D plot of the beam irradiance, and report the diameter of the shaft at 1000 µW/cm2 and 200 µW/cm2.

- For hand-held lamps, the distance across at 1000 µW/cm2 must be in any event 5 in/127 mm.

ASTM E3022, FIG. 1

Example of Beam Irradiance Profile

Planning the Beam Irradiance Profile requires a committed apparatus to mount the lamp and hold it consistent while estimations are taken. It’s critical to utilize an apparatus to hold the lamp set up for the full test. That is because UV-A intensity keeps the backwards square law, so any little changes somewhere out there to the UV-A meter are duplicated and will slant the outcomes. Planning the Beam Irradiance Profile likewise requires some serious energy. Only for the base 5 in/127 mm pillar distance across, the 2-D guide needs in any event 170 separate estimations. The full Beam Irradiance Profile out to 200 µW/cm2 can mean 4 fold the amount of information and long periods of work. This check is impossible while physically holding the light.

The progressions Airbus has executed with Memorandum ME1720084 will be consolidated into Issue 12 of AITM6-1001.